What we do

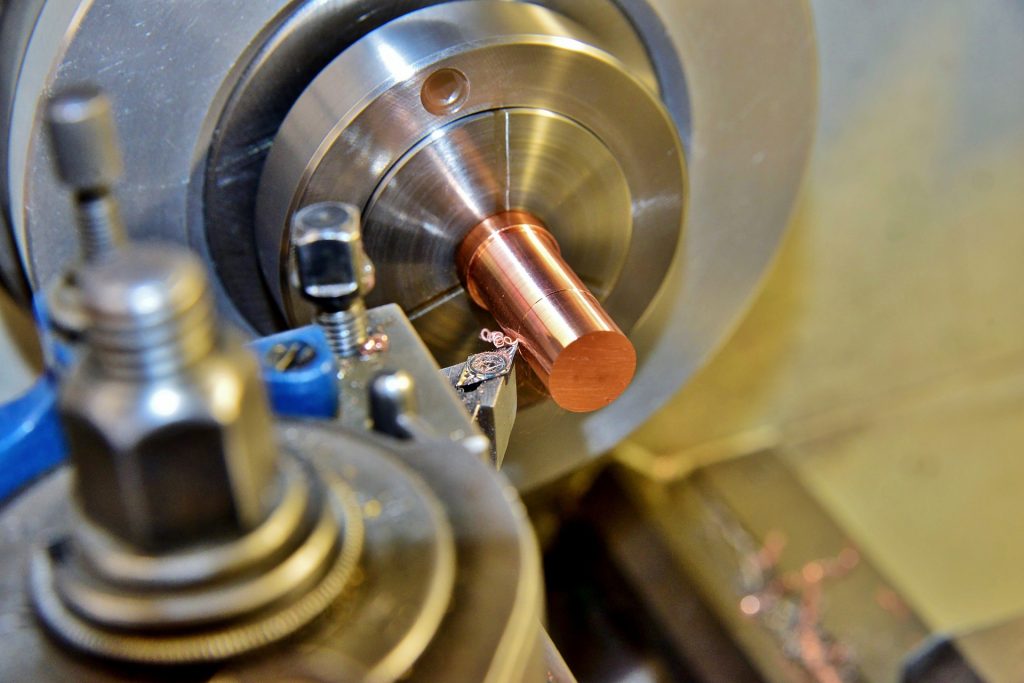

We have a feet of cutting edge technologically enabled CNC computerized machinery and equipment as well as convectional machinery to ensure that world class workmanship expectations are exceeded. Our CNC Programers & Operators are fully trained and certified to do such specialized work.

TriTech Industry has all the facilities and equipment needed to specialize in our field of manufacturing products & services and boasts a large fleet of in-house Induction Foundry and Testing facilities that are of the latest technologies available worldwide.

TriTech Industry & our subsidiary companies employ more than 100 workersin our dynamic team of experts that are trained and qualified to render a superior product line of locally manufactured goods and services.

TriTech Industry has recently purchased the old Marthinusen & Coutts Building in Welkom to expand our operations and to increase our current capacity of the proudly South African Products & Services that we are so well known for. This expansion plan will mark our company as one of the largest manufacturing companies in South Africa and will aim to train and employ another 100 staff members.

TriTech Industry is also the exclusive O.E.M manufacturing house of the renowned TriTech Industrial Product Line & Services.

TriTech Industry will be one of the first companies in South Africa to embark on such a tremendously large capacity of locally manufactured products.

We are very excited to pursue this expansion venture and believe that you will also be pleased to see this forward step towards our governments aim’s and objectives to increase jobs and skill developments in our own country. The success of this venture, of course depends largely upon our own efforts, but we are equally dependent upon the support of all our valued customers, we are counting on your support and co-operation to make this adventure a success.